Hemp production involves a meticulous process of transforming the versatile cannabis plant into durable and sustainable hemp fabric. The fibers used to create hemp fabric are derived from the outer layer of the Cannabis sativa plant’s stalk. These fibers are known for their exceptional qualities, making hemp fabric a popular choice in the textile industry.

After the hemp stalks are harvested, they undergo a series of steps to extract and refine the valuable bast fibers. The stalks are retted to remove pectins and then broken, separating the bast fibers from the woody core. These fibers are thoroughly cleaned, carded to align them, and spun into yarn. The final step involves weaving the yarn into fabric, creating a versatile material for various textile applications.

How is Hemp Made

Hemp fabric is renowned for its durability, softness, breathability, and resistance to mold and mildew. It is commonly used in the production of apparel, such as T-shirts and jackets, but it can also be found in home textiles like towels and upholstery. The demand for hemp fabric has been steadily increasing, with more countries legalizing its cultivation and recognizing its potential in various industries.

China is currently the largest producer of hemp fabric, followed by France, Austria, Chile, and the United Kingdom. As the industrial hemp industry continues to grow, there are promising market opportunities for hemp products, particularly in the food and beverage, textile, and personal care sectors.

Key Takeaways:

- Hemp production involves extracting fibers from the outer layer of the cannabis plant’s stalk.

- The fibers are cleaned, carded, spun into yarn, and woven into durable and sustainable fabric.

- Hemp fabric is known for its durability, softness, breathability, and resistance to mold and mildew.

- Hemp fabric is used in various textile applications, including apparel and home textiles.

- China is the largest producer of hemp fabric, with other countries also investing in hemp cultivation.

The journey of hemp fabric begins with the cultivation of the versatile hemp plant, which shares similarities with organic cotton in terms of growth and sustainability. Hemp, scientifically known as Cannabis sativa, is specifically bred to have low levels of THC, the psychoactive component of cannabis, making it suitable for industrial purposes. The plant thrives in a variety of climates and soil types, making it a highly resilient and adaptable crop.

When cultivating hemp, farmers plant seeds or propagate seedlings in well-drained soil and ensure proper irrigation. The plant grows quickly and densely, reaching heights of up to 16 feet in just a few months. It requires minimal pesticide and herbicide use due to its natural pest resistance and ability to outcompete weeds, making it an environmentally friendly alternative to conventional cotton crops.

Cultivating Hemp: A Sustainable Choice

Hemp cultivation offers several sustainability benefits. Unlike cotton, which requires extensive irrigation and often depletes soil nutrients, hemp can thrive with significantly less water and requires minimal fertilizer. Additionally, hemp’s dense growth pattern helps prevent soil erosion, making it an excellent choice for sustainable farming practices.

| Benefits of Hemp Cultivation | Benefits of Organic Cotton Cultivation |

|---|---|

| Requires less water and fertilizer | Lower pesticide use |

| Prevents soil erosion | Preserves soil quality |

| Thrives in various climates | Adapts to different growing conditions |

By choosing hemp over traditional cotton, consumers can support sustainable farming practices and contribute to a greener future.

“Hemp cultivation offers several sustainability benefits. Unlike cotton, which requires extensive irrigation and often depletes soil nutrients, hemp can thrive with significantly less water and requires minimal fertilizer.”

- Hemp plants are cultivated.

- Minimal pesticides and herbicides are used

- Thrives with less water and fertilizer

- Prevents soil erosion

With the cultivation stage complete, the next step in the journey of hemp fabric is harvesting the plant and extracting its valuable bast fibers.

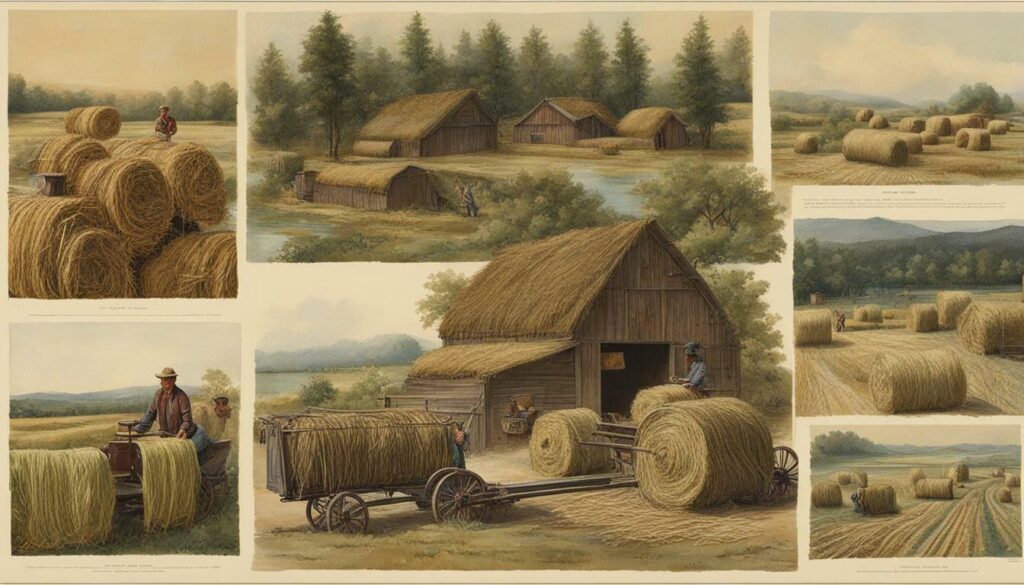

Harvesting Hemp

Once fully grown, hemp plants are carefully harvested to obtain the bast fibers found in their sturdy stalks. This crucial step in the hemp production process involves cutting down the plants and separating the valuable fibers from the rest of the plant material.

The stalks of the hemp plant are the primary source of bast fibers, which are known for their strength and durability. In order to extract these fibers, the harvested hemp stalks undergo a process called retting. Retting involves soaking the stalks in water or exposing them to the elements, which helps to break down the pectins that hold the fibers together. After retting, the stalks are broken into smaller pieces to separate the bast fibers from the woody core.

The bast fibers obtained from the hemp stalks are long and flexible, making them ideal for textile production. These fibers are then cleaned to remove any impurities and prepared for further processing. The cleaned fibers are carded, which involves aligning and straightening them to create a more uniform texture. Once carded, the fibers are spun into yarn, ready to be woven into fabric.

“Hemp fibers are known for their strength and versatility, making them an excellent choice for sustainable textile production.”

Hemp fabric is highly sought after due to its numerous desirable qualities. It is known for being durable, soft, breathable, and resistant to mold and mildew. These properties make it an excellent choice for clothing and home textiles. Hemp fabric is commonly used in the production of items such as T-shirts, jackets, towels, and upholstery. Its versatility and sustainability benefits have contributed to the growing popularity of hemp textiles in the fashion and textile industries.

In terms of global hemp fabric production, China leads the way as the largest producer, followed by France, Austria, Chile, and the United Kingdom. These countries have recognized the potential of hemp as a sustainable fabric and have invested in its cultivation and production. As more countries legalize hemp cultivation and embrace its eco-friendly qualities, there are significant market opportunities for hemp products across various industries, including food and beverage, textiles, and personal care.

Overall, the process of turning hemp plants into fabric involves several essential steps, from harvesting and retting to cleaning, carding, spinning, and weaving. The resulting hemp fabric is durable, versatile, and sustainable, making it an excellent choice for those looking for environmentally friendly textile options.

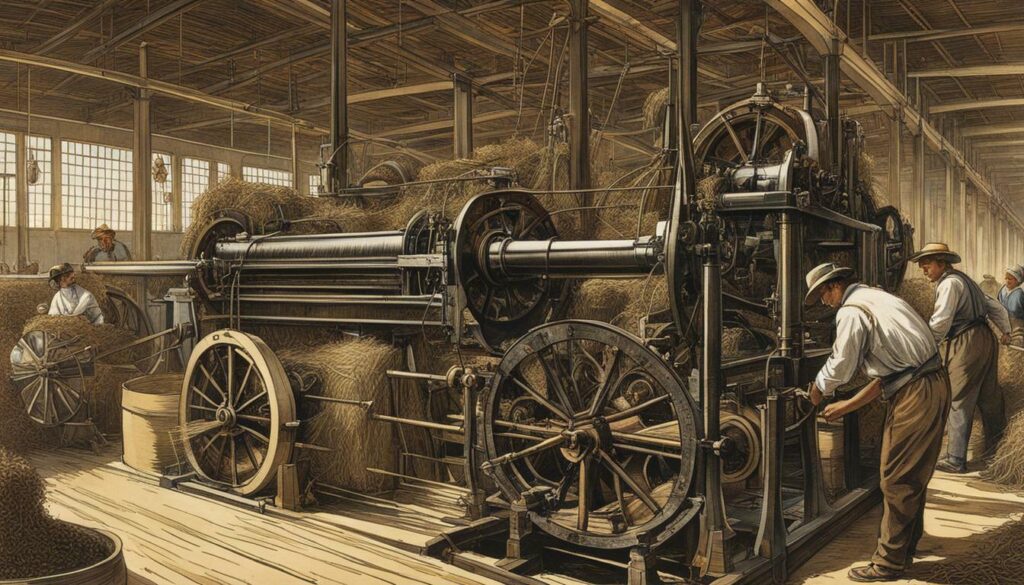

Retting and Breaking

After harvesting, the hemp stalks undergo a retting process to separate the bast fibers, which hold the key to creating hemp fabric, from the sturdy woody core. Retting involves exposing the stalks to moisture and microbial activity, which breaks down the pectins that bind the fibers to the woody core. This process can take anywhere from a few days to several weeks, depending on the desired quality of the fiber.

Once the retting process is complete, the next step is breaking, where the stalks are mechanically crushed to further separate the bast fibers. This can be done through methods like scutching, which involves beating the stalks with wooden tools, or decortication, which uses machinery to strip away the outer layer of the stalk. The goal is to remove as much of the woody core as possible, leaving behind clean and long fibers.

The resulting bast fibers are then ready to be cleaned and processed further, transforming them into the versatile material that is used to create hemp fabric. These fibers are known for their strength and durability, making them ideal for textile applications.

| Hemp Plant | Hemp Stalk | Bast Fibers | Woody Core |

|---|---|---|---|

| Part of Cannabis sativa | Main source of fiber | Used to make hemp fabric | Separated in breaking process |

| Low THC content | Retted to remove pectins | Strong and durable | Discarded or used for other purposes |

| Fast-growing | Harvested and processed | Long fibers suitable for spinning | Less valuable for textile applications |

Retting and breaking are crucial steps in the process of turning hemp stalks into usable fibers for textile production. Separating the bast fibers from the woody core ensures that the resulting fibers are clean, strong, and ready to be transformed into high-quality hemp fabric.

Note: The image above illustrates the process of creating hemp fabric from harvesting, the retting and breaking stages, and then it moves on to the final weaving and production.

“Retting and breaking are essential steps in the production of hemp fabric. Through these processes, the valuable bast fibers are separated from the woody core, resulting in fibers that are ready to be cleaned, carded, and spun into yarn. This allows for the creation of durable and versatile hemp fabric that is used in various textile applications.”

Cleaning and Carding

Cleaned and free of impurities, the hemp fibers undergo carding to align them and ensure a smooth spinning process, which is essential for creating high-quality hemp fabric. Carding involves combing the fibers to remove any remaining debris and to create a consistent and uniform texture. This process also helps to separate and straighten the fibers, making them easier to spin into yarn.

During carding, the hemp fibers pass through a series of fine-toothed brushes or carding machines. These machines work by teasing the fibers apart and aligning them in parallel strands. As a result, the carded fibers form a web-like sheet, known as a sliver, which is then ready for the spinning process.

Carding hemp not only improves the quality of the fibers but also enhances their ability to be spun into yarn. The carded hemp are now ready for the next step in the process, spinning, which transforms the fibers into a strong and versatile material that can be used to create various hemp fabric products.

Spinning Hemp Fibers

Through the art of spinning, the aligned hemp fibers are skillfully twisted together to form strong and versatile yarn, a crucial component in the production of hemp fabric. This process involves carefully extracting the hemp fibers from the stalks and aligning them in a consistent direction to maximize their strength and durability.

The spun hemp yarn can vary in thickness and texture, depending on the desired end use. It can be fine and smooth for delicate fabrics or thicker and more textured for sturdier applications. The resulting yarn is known for its natural luster and softness, making it a popular choice for clothing and other textile products.

During the spinning process, special machines are used to twist the hemp fibers together, creating a continuous thread that is then wound onto bobbins or spools. The tension and speed of the spinning machines are carefully controlled to ensure the desired yarn thickness and uniformity.

Hemp yarn can be used in a wide range of applications, from apparel and accessories to home textiles. Its strength and durability make it suitable for everyday wear, while its breathability and moisture-wicking properties provide comfort in various climates.

| Advantages of Spun Hemp Yarn: |

|---|

| 1. High tensile strength and durability |

| 2. Soft and comfortable against the skin |

| 3. Naturally breathable and moisture-wicking |

| 4. Resistant to mold and mildew |

| 5. Versatile in thickness and texture for various applications |

Overall, the spinning of hemp fibers is a crucial step in the production of hemp fabric. It transforms the raw fibers into a versatile and sustainable yarn that can be woven into a wide range of textile products. With its numerous benefits and growing demand for eco-friendly materials, hemp fabric is becoming increasingly popular in the fashion and textile industry.

Weaving Hemp Fabric

The spun hemp yarn is carefully woven to create the highly sought-after hemp fabric, renowned for its durability, breathability, and wide range of applications. With its natural fibers, hemp fabric has a distinct texture and appearance that sets it apart from other textiles. It is known for its strength, making it ideal for garments and home textiles that need to withstand frequent use and washing.

Hemp fabric is incredibly versatile and can be woven into various patterns and styles. From plain weaves to twills and even intricate designs, hemp fabric offers a range of possibilities for fashion designers and textile enthusiasts. The natural color of the hemp fiber, ranging from creamy whites to earthy browns, adds to the aesthetic appeal of the fabric.

Not only is hemp fabric durable and aesthetically pleasing, but it is also highly breathable. The fibers allow air to circulate freely, keeping the wearer cool and comfortable. This makes hemp clothing an excellent choice for warm climates or physical activities where breathability is essential. Additionally, hemp fabric has natural antimicrobial properties, making it resistant to mold and mildew, ensuring freshness and odor control.

| Advantages of Hemp Fabric | Applications |

|---|---|

| Hypoallergenic and gentle on the skin | Apparel: T-shirts, dresses, jackets |

| Moisture-absorbent and temperature-regulating | Home textiles: Towels, bed linens, upholstery |

| Eco-friendly and sustainable | Industrial uses: Canvas, sacks, rope |

Whether it’s a cozy hemp sweater or a stylish hemp tote bag, the appeal of hemp fabric continues to grow. Its durability, breathability, and sustainable nature make it a popular choice among eco-conscious and fashion-forward individuals. With its versatility and natural charm, hemp fabric will revolutionize the textile industry and pave the way for a more sustainable future.

Due to its remarkable qualities and wide range of applications, Hemp fabric finds its way into various industries, from fashion and home textiles to paper production and specialty items like hemp rope. With its strong and durable nature, hemp fabric is popular for clothing manufacturers seeking sustainable alternatives to traditional fabrics. The hemp fibers are similar to linen, offering a soft and breathable texture that provides comfort in warm and cool climates. This makes hemp clothing a versatile and practical choice for everyday wear.

Aside from its use in the fashion industry, hemp fabric is also utilized in the production of paper. Hemp paper is known for its strength and durability, making it ideal for printing, packaging, and even currency. Its long fibers contribute to the overall quality and longevity of the paper, ensuring that it can withstand frequent handling.

Furthermore, hemp fabric is a key ingredient in the production of specialty items such as hemp rope. The strong and resilient fibers of hemp make it an excellent choice for ropes used in various industries, including boating, construction, and agriculture. Hemp rope is known for its durability and resistance to UV rays, moisture, and abrasion, making it a reliable choice for demanding applications.

| Hemp Clothing | Hemp Paper | Hemp Rope |

|---|---|---|

| – Durable and breathable fabric – Versatile for all types of clothing – Sustainable alternative to conventional fabrics | – Strong and long-lasting material – Ideal for printing and packaging – Resistant to wear and tear | – Reliable and resilient rope – Withstands harsh environmental conditions – Suitable for various industries |

With its various uses and remarkable properties, hemp fabric continues to gain popularity as a sustainable alternative in numerous industries. From the fashion world to paper production and specialty items like hemp rope, the versatility of hemp fabric showcases its potential for a greener future. As more countries legalize the cultivation of industrial hemp, market opportunities for hemp products are steadily increasing, providing new avenues for exploration and innovation in the food and beverage, textile, and personal care industries.

With its sustainable production methods and wide-ranging applications, hemp fabric is paving the way for a more environmentally friendly and socially responsible fashion and textile industry. Its durability, breathability, and resistance to mold and mildew make it an excellent choice for clothing, upholstery, and home textiles. As the largest producer of hemp fabric, China leads the way in this growing industry, followed by France, Austria, Chile, and the United Kingdom. With the increasing global interest in sustainable materials, the demand for hemp fabric is expected to continue rising, creating exciting opportunities for businesses and consumers alike.

Global Hemp Fabric Production

China takes the lead as the largest producer of hemp fabric, closely followed by France, Austria, Chile, and the United Kingdom, in a flourishing global hemp industry fueled by the legalization of hemp cultivation and the emerging market demand. The production of hemp fabric has gained momentum as more countries recognize the economic and environmental benefits of this versatile material.

China’s dominance in hemp fabric production can be attributed to its long history of cultivating hemp and its well-established infrastructure for processing and manufacturing. French hemp fabric production has also seen significant growth, with the country capitalizing on its expertise in textile production and sustainable farming practices.

The global demand for hemp fabric is driven by consumers’ increasing preference for sustainable and eco-friendly materials. Hemp’s ability to grow without the need for pesticides or herbicides, its high yield per acre, and its low ecological footprint make it an attractive choice for both manufacturers and environmentally conscious consumers. This growing demand has created new market opportunities for hemp products, particularly in the food and beverage, textile, and personal care industries.

| Rank | Country |

|---|---|

| 1 | China |

| 2 | France |

| 3 | Austria |

| 4 | Chile |

| 5 | United Kingdom |

In conclusion, the global hemp fabric industry is experiencing rapid growth, with China leading the way as the largest producer. France, Austria, Chile, and the United Kingdom have also emerged as key players in this thriving market. The legalization of hemp cultivation and the increasing market demand for sustainable and eco-friendly materials have fueled the expansion of the hemp fabric industry. With its numerous environmental benefits and versatile applications, hemp fabric is set to continue its rise as a sustainable alternative in the textile industry.

References:

- “China Becomes the World’s Largest Hemp Textile Production Base.” China Chamber of Commerce for Import and Export of Foodstuffs, Native Produce and Animal By-Products (CFNA), www.cfna.org.cn/BR_BRNews/BRIndustry/201910/t20191024_323587.shtml.

- “Hemp Today – Daily News on Industrial Hemp and Cannabis.” HempToday, www.hemptoday.net.

- “Sustainability of Hemp Textiles: A Review.” Journal of Textiles, Hindawi, 27 June 2019, www.hindawi.com/journals/jtex/2019/1757976/.

As consumers increasingly prioritize sustainable options, hemp emerges as a frontrunner in the pursuit of eco-friendly textiles, with its myriad benefits making it the go-to choice for those seeking the best in sustainable fabric. Hemp fabric is not only durable and versatile but also boasts several environmental advantages that set it apart from other materials.

One of the key benefits of hemp fabric is its minimal environmental impact. The cultivation of hemp requires significantly less water compared to other crops, making it a more sustainable choice. Additionally, hemp crops naturally suppress weed growth, reducing the need for harmful herbicides and pesticides. This makes hemp an ideal alternative for those looking to minimize the ecological footprint of their clothing and textile choices.

Hemp is also a highly renewable resource. The hemp plant grows quickly and efficiently, reaching maturity in just a few months. Its rapid growth cycle allows for multiple harvests in a single year, ensuring a steady supply of raw materials for fabric production. This renewable nature of hemp makes it an attractive option for sustainable development and a vital resource for researchers and innovators looking to further the hemp revolution.

Moreover, hemp is biodegradable, which means that at the end of its life cycle, it naturally decomposes without leaving behind harmful pollutants. This makes hemp fabric a preferred choice for those who prioritize reducing waste and embracing a circular economy. By choosing hemp, individuals can enjoy the best in sustainable fabric while aligning with their environmental values.

| Benefits of Hemp Fabric |

|---|

| Hemp requires less water for cultivation compared to other crops. |

| Hemp naturally suppresses weed growth, reducing the need for harmful herbicides and pesticides. |

| Hemp is a highly renewable resource, with a quick growth cycle and multiple harvests per year. |

| Hemp fabric is biodegradable, minimizing waste and supporting a circular economy. |

“Hemp emerges as a frontrunner in the pursuit of eco-friendly textiles, with its myriad benefits making it the go-to choice for those seeking the best in sustainable fabric.”

Conclusion

The intricate process of transforming hemp fibers into durable and sustainable hemp fabric showcases the remarkable journey this versatile plant takes to become a key player in the production of eco-friendly textiles. Hemp fabric is made from the fibers of the Cannabis sativa plant, specifically the outer layer of the stalk. After the stalks are harvested, they are retted to remove pectins and then broken to separate the bast fibers from the woody core.

The fibers go through a thorough cleaning and carding process before being spun into yarn. This yarn is then woven into fabric, resulting in a durable, soft, and breathable material that is resistant to mold and mildew. Hemp fabric finds its primary use in apparel, including T-shirts and jackets, but it can also be found in home textiles like towels and upholstery, offering a natural and sustainable alternative to conventional materials.

China is currently the largest producer of hemp fabric, followed by France, Austria, Chile, and the United Kingdom. With more countries legalizing hemp cultivation, the industrial hemp industry is experiencing growth, creating market opportunities for hemp products across various industries, including food and beverage, textile, and personal care.

In a world increasingly focused on sustainability, hemp fabric stands out as a truly eco-friendly option. Its cultivation requires fewer pesticides and water compared to other crops, and it has a smaller carbon footprint. Additionally, hemp plants can enrich and improve soil quality, making it a beneficial crop for farmers. As demand for sustainable fabrics grows, hemp is positioned to play a significant role in shaping a greener future for the textile industry.

Frequently Asked Questions

Q: How is hemp fabric made?

A: Hemp fabric is made from the fibers of the Cannabis sativa plant, specifically the outer layer of the stalk. The stalks are harvested, retted to remove pectins, and then broken to separate the bast fibers from the woody core. The fibers are cleaned, carded, spun into yarn, and woven into fabric.

Q: What are the characteristics of hemp fabric?

A: Hemp fabric is known for being durable, soft, breathable, and resistant to mold and mildew. It is a sustainable and eco-friendly option for textiles.

Q: What are the applications of hemp fabric?

A: Hemp fabric is primarily used in apparel, such as T-shirts and jackets, but can also be used in home textiles like towels and upholstery. It has diverse applications in the textile industry.

Q: Which countries are the largest producers of hemp fabric?

A: China is the largest producer of hemp fabric, followed by France, Austria, Chile, and the United Kingdom.

Q: Is there a growing market for hemp products?

A: Yes, the industrial hemp industry is growing, with more countries legalizing its cultivation. There are market opportunities for hemp products, particularly in the food and beverage, textile, and personal care industries.

0 Comments